Boat Building - PVC Skin

Attaching

All kinds of coamings - wood and fiberglass - can be attached with Velcro on the inside edge of the coaming. The inside Velcro connection is more watertight than the foam seal used with the HDPE coaming / baseplate. This also allows use of the coaming without a base plate, though a temporary base plate is used for construction only.

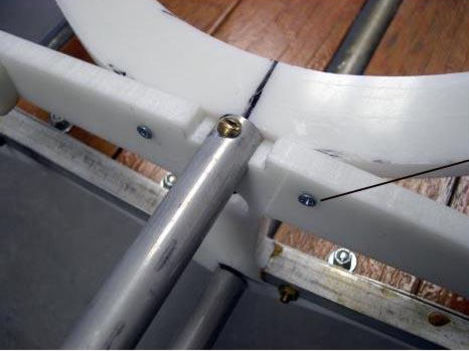

Due to it's narrow profile, the wood coaming is free standing and uses

no machine screw connections as are used with the HDPE and fiberglass

coamings. With it's wider profile, the fiberglass coaming can be

connected to cross sections 4 and 5 with stainless steel machine screws.

The use of machine screw attachments allow more rigidity along the

deckridge.

Free Standing Wood Coaming

The freestanding wood coaming was designed and built by Mark Molina.

The result: Freestanding wood coaming as designed by Mark Molina

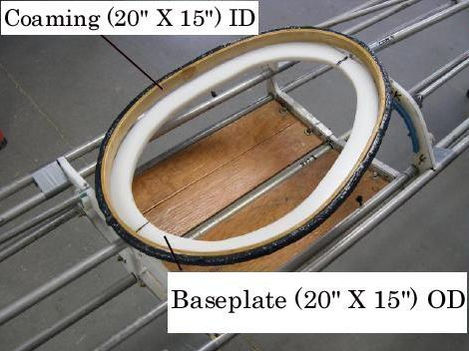

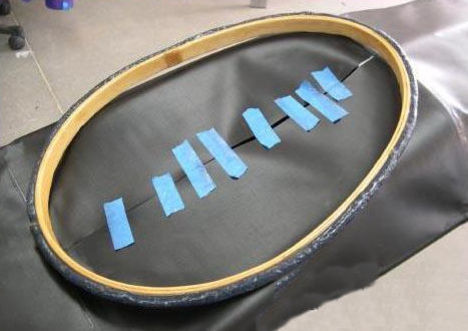

The temporary base plate fits flush with the top of cross section 4 and 5.

It allows a smooth transition between the PVC skin and the coaming during construction work.

It is held in place with screws, and it is removed after the coaming is atttached.

Baseplate with prebuilt wooden coaming

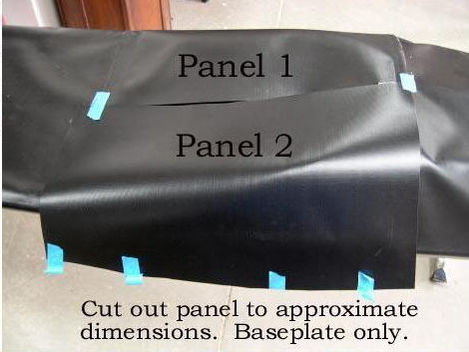

Cut out panel to approximate dimensions with underlying baseplate only

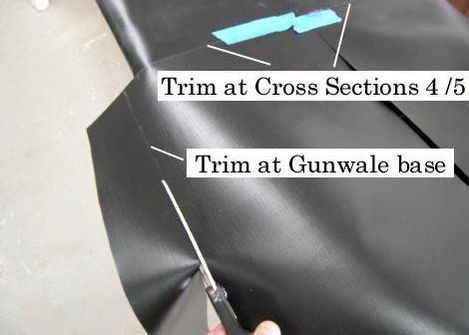

Trim deck skin at cross sesctions 4 and 5 and at gunwales

Tape 1/8" outside of edge of baseplate to establish glue border

Apply 2 - 3 coats of Vinyl glue to the PVC skin

Apply 2 - 3 coats of Vinyl glue to the coaming panel

Use a heat gun and apply hand pressure to glue the PVC parts together

Tape the two coaming panels together before cutting the opening

Use a sharp knife to cut the PVC Skin along the inside edge of the baseplate (temporary coaming)

Important change of the method shown below

This is a change from the earlier method as shown here of

gluing adhesive backed Velcro directly to the PVC panels.

Gluing

self-adhesive Velcro to the coaming (wood or fiberglass) or to PVC has

not shown long term durability.

And this is how it must be done

Glue non-adhesive Velcro (hook) to

the inside coaming using thickened epoxy resin or epoxy glue. As an

quick alternative, 5-minute epoxy can be used.

Sew the The Velcro (loop) to a 1.25in strip of PVC before glueing to

the 2" wide PVC panels.

Glue 1" wide Velcro (hook side) to the inside of the coaming

Attach 1" wide Velcro (loop side) to the Velcro hook section.

Cut slits in PVC about every 2".

Mask glueing areas and apply 2 - 3 coats of Vinyl glue

After the glue dried, tape the 2" PVC sections to Velcro

Glue sides together with heat and pressure

Remove the temporary baseplate

Cut a 1.25" wide strip of PVC to cover and waterproof the inside of the coaming

Apply 2 - 3 coats of Vinyl glue to the inside of the coaming

The result - mounted

Freestanding wood coaming - dismounted